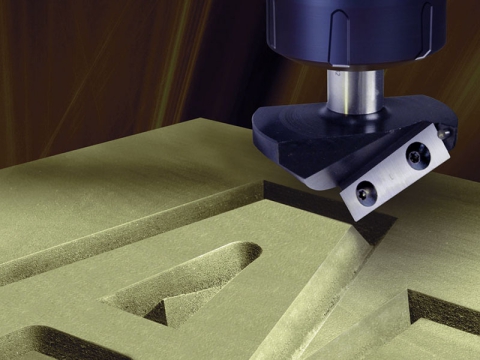

數(shù)控雕刻機(jī) is a combination of cutting, carving and milling in terms of processing principle, and the 數(shù)控雕刻機(jī) has multiple data input modes as needed. Because the application range is very wide, it is necessary to understand the most suitable application range of 數(shù)控雕刻機(jī). Low-power數(shù)控is only suitable for making signs, crafts, gifts, and molds. Because the power is too small, it greatly affects the scope of its application. High-power數(shù)控can be used as a small-power數(shù)控. It is most suitable for large-scale cutting, milling, and carving.

Computers and 數(shù)控雕刻機(jī) have no intelligence. They cannot think, they cannot evaluate a station in a rational way. Only people with certain skills and knowledge can do that. In the field of numerical control, the skills are usually in the hands of 2 key people- one doing the programming, the other doing the machining. Their respective numbers and duties typically depend on the company preference, its size, as well as the product manufactured there. However, each position is a quite distinct, although many companies combine the 2 functions into a one, often called a數(shù)控programmer or 數(shù)控雕刻機(jī) operator.

CNC程序員

數(shù)控程序員通常是數(shù)控機(jī)加車間中責(zé)任最大的人。此人通常負(fù)責(zé)工廠中數(shù)控技術(shù)的成功。同樣,此人還負(fù)責(zé)與數(shù)控操作相關(guān)的問(wèn)題。盡管職責(zé)可能有所不同,但程序員還負(fù)責(zé)與數(shù)控機(jī)床的有效使用相關(guān)的各種任務(wù)。事實(shí)上,此人通常負(fù)責(zé)所有數(shù)控操作的生產(chǎn)和質(zhì)量。

許多數(shù)控程序員都是經(jīng)驗(yàn)豐富的機(jī)械師,他們擁有實(shí)際的動(dòng)手操作機(jī)床的經(jīng)驗(yàn),他們知道如何閱讀技術(shù)圖紙,并能理解設(shè)計(jì)背后的工程意圖。這種實(shí)踐經(jīng)驗(yàn)是能夠在辦公室環(huán)境中“加工”零件的基礎(chǔ)。優(yōu)秀的數(shù)控程序員必須能夠直觀地看到所有工具運(yùn)動(dòng)并識(shí)別可能涉及的所有限制因素。程序員必須能夠收集、分析過(guò)程并將所有收集的數(shù)據(jù)邏輯地集成到一個(gè)信號(hào)、有凝聚力的程序中。簡(jiǎn)而言之,數(shù)控程序員必須能夠從各個(gè)方面決定最佳的制造方法。

除了機(jī)械加工技能外,數(shù)控程序員還必須了解數(shù)學(xué)原理,主要是方程的應(yīng)用、弧和角的解。三角學(xué)知識(shí)也同樣重要。即使使用計(jì)算機(jī)編程,手動(dòng)編程方法的知識(shí)對(duì)于徹底理解計(jì)算機(jī)輸出和控制此輸出也是絕對(duì)必要的。

真正專業(yè)的數(shù)控程序員的最后一個(gè)重要素質(zhì)是傾聽其他人(工程師、數(shù)控操作員、經(jīng)理)的能力。良好的傾聽技巧是變得靈活的第一個(gè)先決條件。優(yōu)秀的數(shù)控程序員必須靈活才能提供高質(zhì)量的編程。

數(shù)控雕刻機(jī) Operator

The數(shù)控machine tool operator is a complementary position to the數(shù)控programmer. The programmer and the operator may exist in a single person, as is the case in many small shops. Although the majority of duties performed by conventional machine operator has been transferred to the數(shù)控program, the數(shù)控operator has many unique responsibilities. In typical cases, the operator is responsible for the tool and machine setup, for the changing of the parts, often even for some in-process inspection. Many companies expect quality control at the machine – and the operator of any machine tool, manual or computerized, is also responsible for the quality of the work done on that machine. One of the very important responsibilities of the 數(shù)控雕刻機(jī) operator is to report findings about each program to the programmer. Even with the best knowledge, skills, attitudes and intentions, the "final" program can always be improved. The數(shù)控operator being the one, who is the closest to the actual machining, knows precisely what extent such improvements can be.

關(guān)于數(shù)控技術(shù)的傳聞信息很多,機(jī)器供應(yīng)商往往會(huì)快速突出其產(chǎn)品的某些特點(diǎn),同時(shí)盡量減少其他非常重要的特性。

The truth is that in every case the purchaser must make compromises to come up with the solution that best fits their needs. Not one application is exactly the same and not one 數(shù)控雕刻機(jī) will be the perfect fit in every supplier.

What can a 數(shù)控雕刻機(jī) do? Will it replace workers? is my job in jeopardy? these are some of the questions you will face from your employees when you are thinking of buying it.

雖然它可能會(huì)用更高技能的工作取代繁瑣重復(fù)的工作,但大多數(shù)購(gòu)買這項(xiàng)技術(shù)的公司最終都會(huì)發(fā)展壯大并雇用更多員工。

The work that happens downstream from the 數(shù)控雕刻機(jī) will also be impacted. The parts are likely to be more accurate and in the case of nested based systems, they will remain grouped together, simplifying subsequent processes.