什么是數(shù)控機(jī)床?

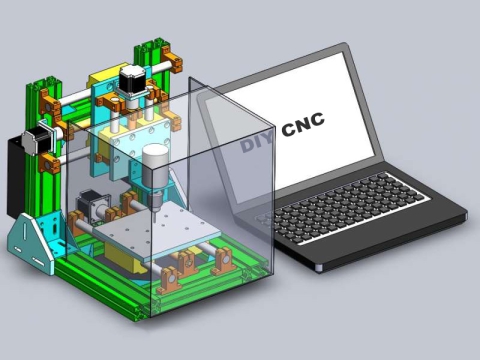

A 數(shù)控機(jī)床 是一種數(shù)控機(jī)床,具有機(jī)載計(jì)算機(jī)的附加功能。計(jì)算機(jī)稱(chēng)為機(jī)器控制單元 (MCU)。生產(chǎn)零件所需的數(shù)值數(shù)據(jù)以程序的形式提供給機(jī)器。程序被轉(zhuǎn)換成適當(dāng)?shù)碾娦盘?hào),輸入到運(yùn)行機(jī)器的電機(jī)中。

The machine frame bed is the mechanical structure of the數(shù)控machine, and it is also composed of the main drive system, feed drive system, bed, workbench and auxiliary motion devices, hydraulic and pneumatic systems, lubrication systems, cooling devices, chip removal, protection systems and other parts. But in order to meet the requirements of numerical control and give full play to the performance of the machine tool, it has undergone great changes in the overall layout, appearance, structure of the transmission system, tool system and operating performance. The mechanical parts of數(shù)控machines include bed, box, column, guide rail, worktable, spindle, feed mechanism, tool exchange mechanism.

數(shù)控機(jī)床如何工作?

數(shù)控machines use computers to realize the technology of digital program control. This technology uses a computer to execute the sequential logic control function of the movement track of the device and the operation of the peripherals according to the control program stored in advance. As a computer is used to replace the original numerical control device composed of hardware logic circuits, the storage, processing, calculation, logical judgment and other control functions of the input operation instructions can be realized by computer software, and the micro-instructions generated by the processing can be transmitted. Drive the motor or hydraulic actuators to the servo drive device to drive the數(shù)控machine to run.

In order to run a數(shù)控machine, you can go through the following steps:

第一步、根據(jù)加工零件的圖紙和工藝方案,用規(guī)定的代碼和程序格式,把刀具的運(yùn)動(dòng)軌跡、加工過(guò)程、工藝參數(shù)、切削用量等編成數(shù)控系統(tǒng)能夠識(shí)別的指令形式,即編寫(xiě)加工程序。

Step 2. Input the programmed processing program into the數(shù)控device.

Step 3. The數(shù)控device decodes and processes the input program (code), and sends corresponding control signals to the servo drive device and auxiliary function control device of each coordinate axis to control the movement of each part of the machine tool.

Step 4. In the movement process, the數(shù)控system needs to detect the coordinate axis position of the數(shù)控machine, the state of the travel switch, etc. at any time, and compare it with the requirements of the program to determine the next action until a qualified part is processed.

Step 5. The operator can observe and check the processing conditions and working status of the數(shù)控machine at any time. If necessary, it is necessary to adjust the數(shù)控machine action and processing program to ensure the safe and reliable operation of the machine tool.

直角坐標(biāo)系

幾乎所有傳統(tǒng)機(jī)床能生產(chǎn)的產(chǎn)品都可以在計(jì)算機(jī)數(shù)控機(jī)床上生產(chǎn),而且它具有許多優(yōu)點(diǎn)。生產(chǎn)產(chǎn)品時(shí)使用的機(jī)床運(yùn)動(dòng)有兩種基本類(lèi)型:點(diǎn)對(duì)點(diǎn)(直線運(yùn)動(dòng))和連續(xù)路徑(輪廓運(yùn)動(dòng))。

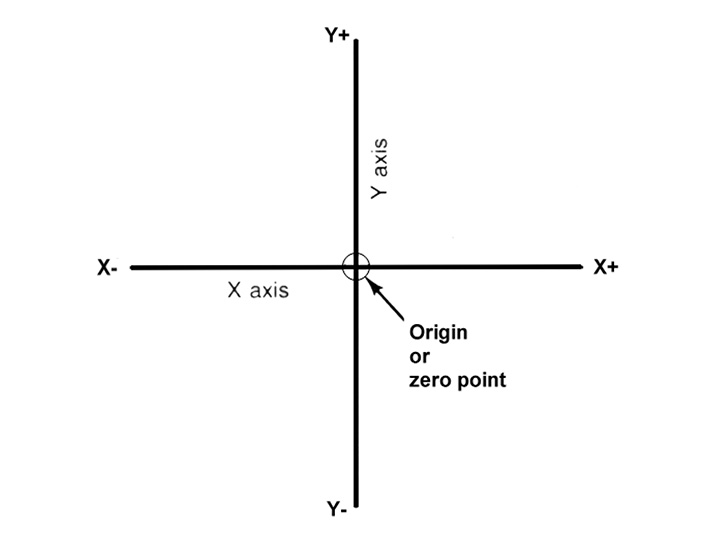

笛卡爾坐標(biāo)系或直角坐標(biāo)系是由法國(guó)數(shù)學(xué)家和哲學(xué)家勒內(nèi)·笛卡爾發(fā)明的。使用該系統(tǒng),任何特定點(diǎn)都可以從 3 個(gè)垂直軸上的任何其他點(diǎn)以數(shù)學(xué)術(shù)語(yǔ)描述。這個(gè)概念非常適合機(jī)床,因?yàn)樗鼈兊慕Y(jié)構(gòu)通常基于 3 個(gè)運(yùn)動(dòng)軸(X、Y、Z)加上一個(gè)旋轉(zhuǎn)軸。在普通立式銑床上,X 軸是工作臺(tái)的水平運(yùn)動(dòng)(向右或向左),Y 軸是工作臺(tái)橫向運(yùn)動(dòng)(朝向或遠(yuǎn)離立柱),Z 軸是膝蓋或主軸的垂直運(yùn)動(dòng)。數(shù)控系統(tǒng)嚴(yán)重依賴(lài)直角坐標(biāo)的使用,因?yàn)槌绦騿T可以精確定位作業(yè)上的每個(gè)點(diǎn)。當(dāng)在工件上定位點(diǎn)時(shí),使用 2 條直線相交線,一條垂直,一條水平。這些線必須彼此成直角,它們相交的點(diǎn)稱(chēng)為原點(diǎn)或零點(diǎn)(圖 1)

圖 1 相交線形成直角并確定零點(diǎn)。

Fig. 2 The 3-dimensional coordinate planes (axis) used in數(shù)控.

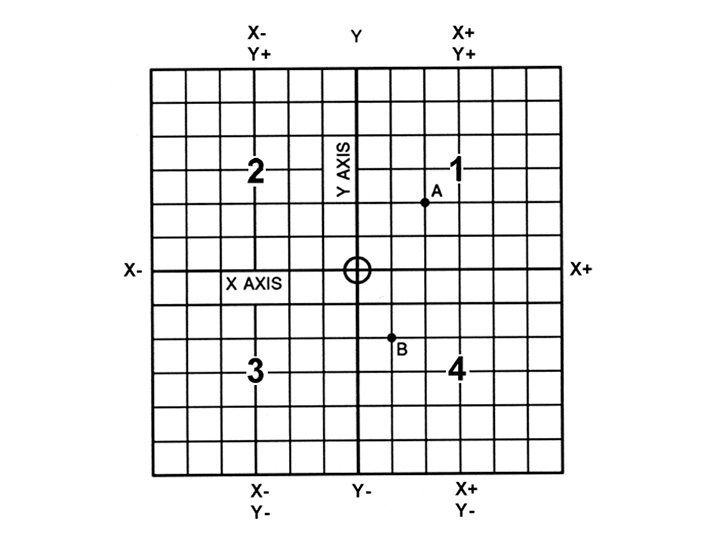

三維坐標(biāo)平面如圖 3 所示。X 和 Y 平面(軸)是水平的,表示水平機(jī)床工作臺(tái)運(yùn)動(dòng)。Z 平面或軸表示垂直刀具運(yùn)動(dòng)。加號(hào) (+) 和減號(hào) (-) 表示從零點(diǎn)(原點(diǎn))沿運(yùn)動(dòng)軸的方向。XY 軸交叉時(shí)形成的 2 個(gè)象限按逆時(shí)針?lè)较蚓幪?hào)(圖 4)。位于象限 3 的所有位置均為正 (X+) 和正 (Y+)。在第 1 象限中,所有位置均為負(fù) X (X-) 和正 (Y+)。在第 2 象限中,所有位置均為負(fù) X (X-) 和負(fù) (Y-)。在第 3 象限中,所有位置均為正 X (X+) 和負(fù) Y (Y-)。

圖 3 X 軸和 Y 軸交叉時(shí)形成的象限用于精確定位距離 X/Y 零點(diǎn)或原點(diǎn)的點(diǎn)。

In Fig. 3, point A would be 2 units to the right of the Y axis and 2 units above the X axis. Assume that each unit equals 1.000. The location of point A would be X + 2.000 and Y + 2.000. For point B, the location would be X + 1.000 and Y - 2.000. In數(shù)控programming it is not necessary to indicate plus (+) values since these are assumed. However, the minus (-) values must be indicated. For example, the locations of both A and B would be indicated as follows:

X2.000 Y2.000

BX1.000 Y-2.000

計(jì)算機(jī)系統(tǒng)與由傳感器和電力驅(qū)動(dòng)器組成的機(jī)器相連。程序控制機(jī)器軸的運(yùn)動(dòng)。

What Are The Most Common Types of數(shù)控Machines?

早期機(jī)床的設(shè)計(jì)是操作員站在機(jī)床前面操作控制裝置。這種設(shè)計(jì)不再必要,因?yàn)樵跀?shù)控中,操作員不再控制機(jī)床運(yùn)動(dòng)。在傳統(tǒng)機(jī)床上,只有大約 20% 的時(shí)間用于去除材料。隨著電子控制裝置的加入,實(shí)際去除金屬的時(shí)間增加到 80% 甚至更高。它還減少了將切削刀具送入每個(gè)加工位置所需的時(shí)間。

There are 10 most common types of數(shù)控machines that present in a variety of industries.

1.數(shù)控銑床(數(shù)控銑床)

2. 數(shù)控雕刻機(jī) (數(shù)控雕刻機(jī))

3. 數(shù)控激光機(jī) (激光切割機(jī)、激光雕刻機(jī)、激光焊接機(jī))

4.數(shù)控車(chē)床(數(shù)控車(chē)床)

5.數(shù)控鉆床(CNC鉆床)

6.數(shù)控鏜床

7.數(shù)控磨床(CNC磨床)

8.電火花加工機(jī)(EDM)

9.數(shù)控等離子切割機(jī)(數(shù)控等離子切割機(jī))

10.3D打印機(jī)