While the specific applications of數控machine vary greatly from one machine to the next, all these sophisticated數控machines have become widely used in a variety of industries. A few of the major benefits offered by數控technology are described below.

省時提效

所有形式的數控機床提供的第一個好處是自動化程度提高。操作員在生產過程中的技能水平可以降低或消除。許多數控機床可以在整個加工周期內無人值守運行,讓操作員可以執行其他任務。這為數控用戶帶來了幾個附帶好處,包括減少操作員疲勞、減少人為錯誤造成的錯誤以及每個工件的加工時間一致且可預測。

平臺精度

數控技術的第二大優勢是工件的一致性和準確性。當今的數控機床的典型精度范圍為 2 至 2 千分之一英寸或 4 至 0.05 毫米,重復性接近或優于 0.10 萬分之一英寸或 0.02mm.這意味著一旦程序經過驗證,就可以輕松生產出具有相同精度和一致性的兩個、十個或一千個相同的工件。

靈活性

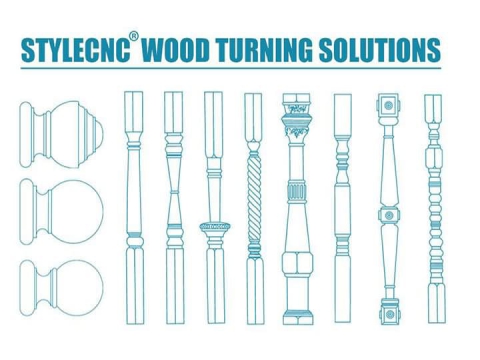

A 3rd benefit offered by most forms of數控machine tools is flexibility. since these machines are run from computer programs, running a different work piece is as easy as loading a different program.

這還帶來了另一個好處,那就是快速轉換。由于這些機器非常容易設置和運行,并且程序易于加載,因此只需要很短的設置時間。這對于當今的即時生產環境至關重要。

The resulting reduction in the number of machines needed in a wood manufacturing shop is yet another benefit worthy of noting. in the past, a great number of dedicated machines were needed to produce furniture or cabinets. With the advent of數控technology, this reality has changed drastically.

工作中心之間耗費的時間越少,生產時間就越快。在制品 (WiP) 越少,庫存就越少,非增值資源的投資就越少。

其結果是,機械需求減少,員工工作量簡化,浪費減少,產量最大化。

The 數控雕刻機 takes no breaks and although the human operator does, he can prepare work for the machine to perform on its own while he is undertaking other work.

例如,公司可以在機器未安排使用時運行雕刻程序。當操作員執行其他工作時,該雕刻程序會運行數小時,從而為企業提供額外的收入。

限制

機器是為了最佳地執行一組功能而制造的,它們本身并不具有與人類相同的移動性和多功能性。新型機器已經發展成為多任務處理和多功能的,雖然數控軟件技術仍然存在一些限制,但數控機床制造商正在不斷改進他們的機器,而富有創造力的用戶正在尋找超越其限制的新使用方法。

嵌入式技能

Since the machine will be running under program control, the skill level required of the數控machine operator is also reduced as compared to a worker producing work pieces with conventional machine tools. of course this is offset by the skill needed in the office to draw and program the parts for the machine.